Truck Side Step

Climbing into the bed of my Dodge 2500 4x4 truck is difficult especially when hooked to my Wildcat. Then I have to climb over the side and can not climb over the tail gate from the rear step bumper.

While traveling I often have to get into the truck bed to refuel the generator or retrieve something from the tool box.

I discussed this with my Dad and we came up with a solution. Think of it as a receiver on the side of the truck.

The step is a piece of diamond plate aluminum bolted to a piece of standard 2 inch square tube steel. The receiver is slightly larger than the standard 2 inch inside measurement. My Dad bought the receiver steel from a junk yard and the owner had a suggestion when my Dad told him what he wanted. The owner suggested a piece of steel that had thinner walls than the standard 2 inch receiver stock. The inside measurement is more like 2 1/8 inches. The owner said regular 2 inch receiver steel would fit too tightly. He said just a small amount of dirt inside would make it difficult to pull out the step.

He was right. There is enough clearance so it works well.

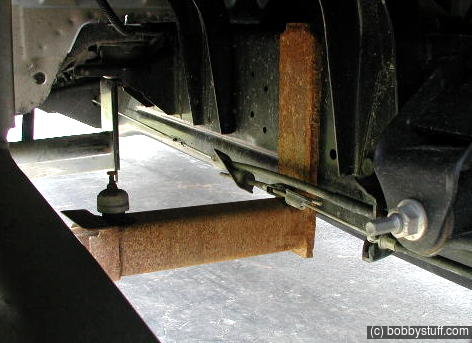

My Dad welded a very strong plate of metal to the end of the receiver steel. He calls it 'T1' steel. His original plan was to drill two holes in the frame and bolt the plate to the frame. However the fuel tank fits so close to the inside of the frame that we could not get our hands between the tank and the frame to put nuts on bolts.

I noticed a hole on top of the frame. We decided to weld a smaller piece of metal to the top of the plate at a 90 degree angle. We drilled a hole in this metal and placed a bolt in the hole that stuck out the bottom about 1/2 inch. He then spot welded the bolt from the top. This bolt fit snugly into the hole in the top of the frame with the longer piece of metal fitting tight against the side of the frame. Think of it as a stud bolt or dowel pin.

It was easy to fit this assembly behind the parking brake cables. Now we just needed a way to hold the assembly tight against the side of the frame. Since we could not get a nut on a bolt because of the fuel tank and the bolt is only to hold the assembly tight to the frame, I suggested we drill a hold in the frame and tap it with threads. The bolt does not have to support any weight.

He drilled a dimple in the top of the 2 inch tube steel and made a spring loaded mechanism that pushes a steel ball bearing into the dimple. The ball rest in the dimple and there is just enough pressure to hold the step in place when pushed in.

I wasn't sure how I would like the step but I have come to enjoy having it. It is easy to pull out. Fueling the generator or accessing the tool box is easy and when I am finished I kick it back in place with my foot.

It looks different but I think it looks fine and it works great.

| Towing Mirrors |

Topics

TagsElectrical (18),Generator (7),Leaks (3),Lights (3),Springs and shackles (7),Tires (3)